S.T.S.

Rotover

This process allows us to achieve excellent aesthetic results while maintaining cost-effectiveness.

Rotover painting enables us to produce parts (made of metal, wood, plastic, or similar materials) that are free of “shadow areas,” even in items that are assembled from multiple parts.

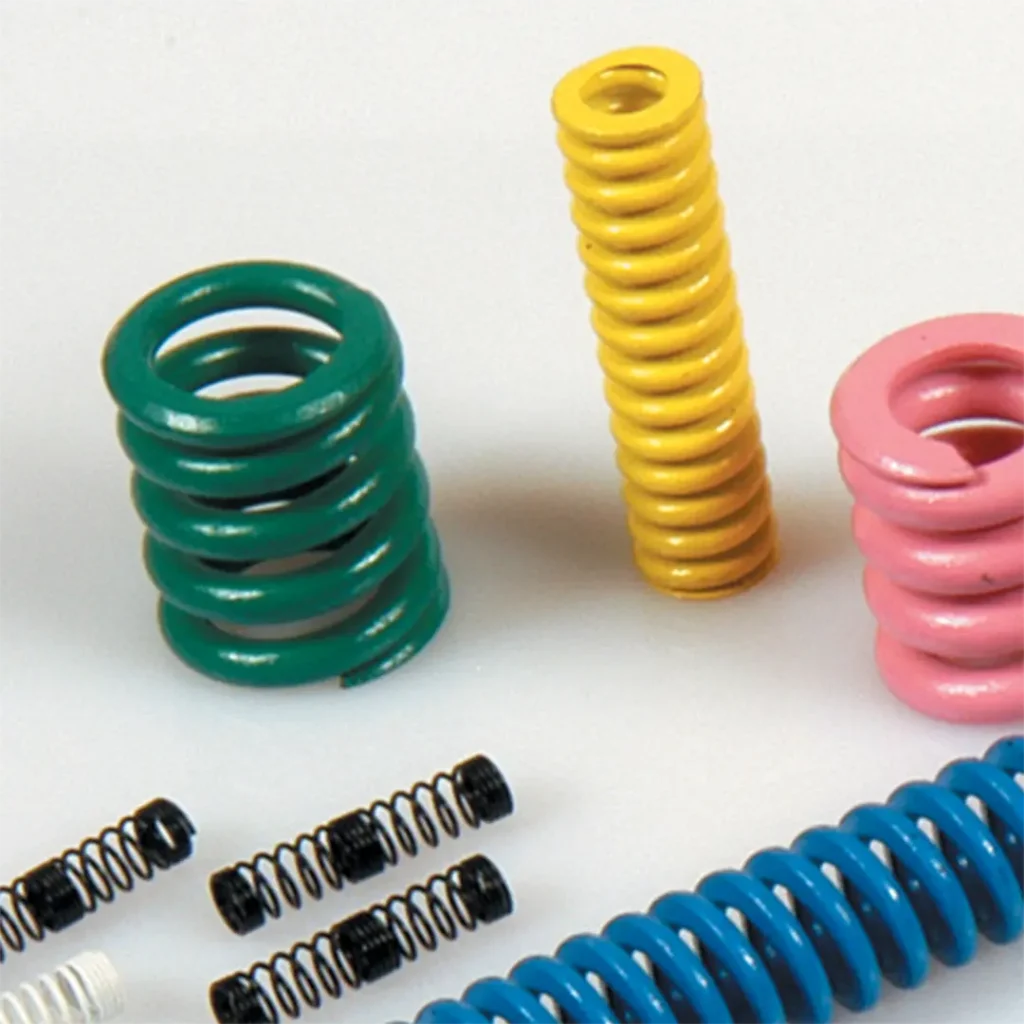

We work with products from various industries, including balance weights, self-tapping screws, pop rivets, bushings, springs of various sizes, buckles, buttons, and more.

Over the years, the range of items we treat has expanded to include new sectors, such as cabinet hinges (small to medium-sized), helmet fastenings, wooden caps for spirits, Allen keys, pins of various types, and more.

Starting from the customer’s specifications, we can combine a wide variety of catalysts and additives to enhance the desired features: elasticity, hardness, opacity, brightness, abrasion resistance, or susceptibility to abrasion.

It is very important to us to carefully manage every phase of the process, including the preparation of small parts before painting.

Compared to galvanizing, our process offers an advantage: we can “play” with colors to create any effect or shade you desire, all while benefiting from the cost-effectiveness of ROTOVER!

We have a line of 15 rotary machines, 4 of which feature 4.0 technology, with plans to replace the remaining standard machines with more advanced models in the coming years.

Rotover with 4.0 System

Between 2020 and 2021, we expanded our production and made significant progress with innovation and technology by creating a new painting line with ROTOVER i4-220p (FEATURING THE 4.0 SYSTEM).

A dedicated program was developed to manage, plan, and control the workstation from a PC or remotely.

In collaboration with our suppliers, after extensive stress tests, the main features of these new machines were defined:

- Reduction and control of consumption

- Precision in the amount of paint dispensed at all times

- Retaining ease of use and maintenance

- Improvement and consistency of the painting process

- Compliance with safety and environmental regulations

- Management of painting cycles (the ability to create, modify, and access a database/history of cycles)